Context

In 2021, demand increased significantly, but the effects of the pandemic continued to affect supply chains.

Delays in the supply of raw materials required operational flexibility and real-time optimization.

Case Study:

Optimizing Supply in the Production Line with Jidoka Kanban

A global automotive components supplier faced frequent supply issues in the SMT production line, resulting in costly downtime and operational inefficiency. By implementing Jidoka Kanban, a digital smart replenishment system, it was possible to:

- Reduced line downtime by 91.2%

- Decreased WIP material inventory by 57%

- ROI achieved in less than 3 months

Context and Challenges

-

-

Challenges:

- Frequent SMT line shutdowns due to missing components.

- Chaotic storage of components in the WIP area.

- Discrepancies between physical stock and SAP inventory.

- Human errors and the lack of a signaling system for the need for materials.

Analysis of the situation

Share IT Smart consultants and the client's team analyzed the situation using 5WHY and Fishbone, identifying the causes of the problems:

-

Operational issues:

-

Lack of a just-in-time supply flow.

-

Reduced visibility of available components.

-

Long time to search and identify components.

Human factors:

-

Errors caused by monotonous processes and high workload.

-

Lack of a digital system to assist operators in real time.

Financial impact:

-

Significant losses caused by line stops.

-

Quality defects due to wrong mixing of components.

-

High inventory costs and expired materials.

Jidoka Kanban Solution

-

Solution Design

Create a new just-in-time supply flow to eliminate human error.

Development of the digital application Jidoka Kanban, which:

- Receive automatic signals directly from SMT equipment.

- Send notifications to the warehouse for real-time replenishment.

- It eliminates repetitive tasks, while maintaining the decision-making flexibility of operators. -

Implementation of the Solution

Planning and training of users.

Return the excess material to the magazine to avoid excessive accumulation in theWIP area.

Results and Impact

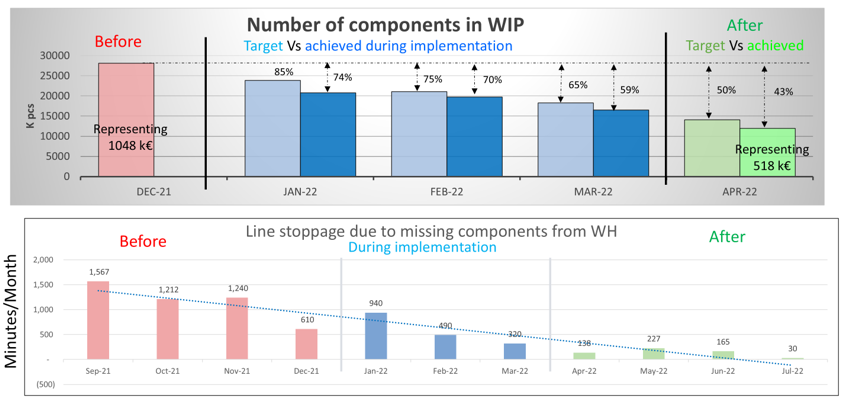

Reduced material inventory in the WIP SMT area by 57%

Reduced line shutdowns due to replenishment by 91.2%

Complete elimination of defects caused by missing or mixing components

Reduction by 50% in the number of operators required to feed the line

Transformation of the process into a paperless system through digitalization

Return of Investment achieved in less than 3 months

Solution Scalability

Extension of the Jidoka Kanban system to all production lines.Integration with Dry Store for managing moisture-sensitive components.

Optimization of production changes (changeover) to maintain the optimal level of stocks.